Regulator Vent Line Mastery: 7 Tips for Regulator Efficiency

Natural gas regulators are essential components of meter sets to ensure safe gas delivery to households and businesses. For them to operate at their best, ventilation must be done properly. This article introduces the IMAC Systems Vent Line Protector (VLP) and examines seven vent line tips.

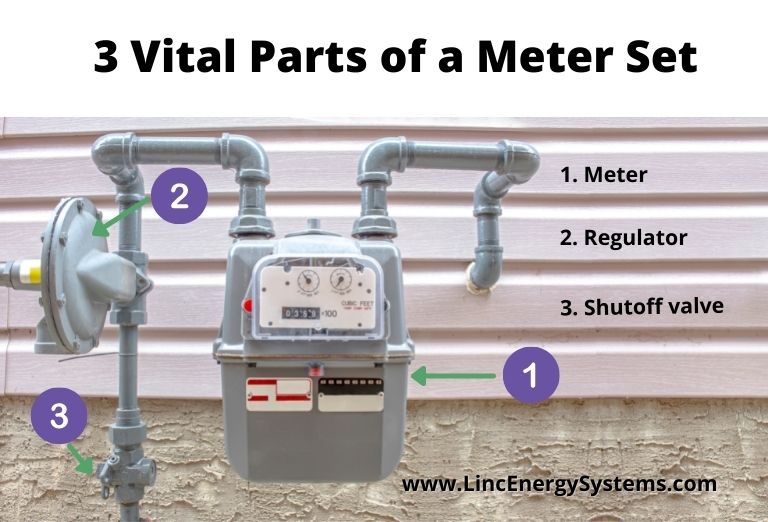

3 Key Components of Natural Gas Meter Sets

Natural gas meter sets contain three vital components to deliver gas to the house safely.

- The gas meter measures gas flow into the building.

- The natural gas regulator reduces and modulates the gas pressure to the meter.

- A shutoff valve on the riser pipe, just below the regulator, provides an emergency shutoff if you smell natural gas in the house. (Note: if the shutoff valve is off, the utility company will likely need to reestablish service, which is a small price to pay in an emergency.)

7 Vent Line Tips

- Minimize Fittings and Long Runs: When plumbing vent lines, avoid excessive fittings or long runs, which can hinder venting efficiency.

- Maintain Proper Pipe Size: Never reduce the vent pipe size from the regulator.

- Outlet Orientation: To keep snow, rain, and debris out of the vent, always turn the outlet down. Position the vent above any possible snow or water lines.

- Bug Screen: Install a bug screen on the vent outlet to prevent insects from building their nests inside the line. Do not cover the screen with paint.

- Roof Clearance: Ensure the vent line clears any places where snow may gather if it runs to a roof. Proper clearance prevents blockages.

- Safe Discharge: Position the vent to discharge away from people, fresh air intakes, and windows. Safety is paramount.

- IMAC Systems Vent Line Protector (VLP)

The IMAC VLP has safeguarded gas regulators during flooding for nearly a decade. Here’s how it works:

Vent Line Protector (VLP)

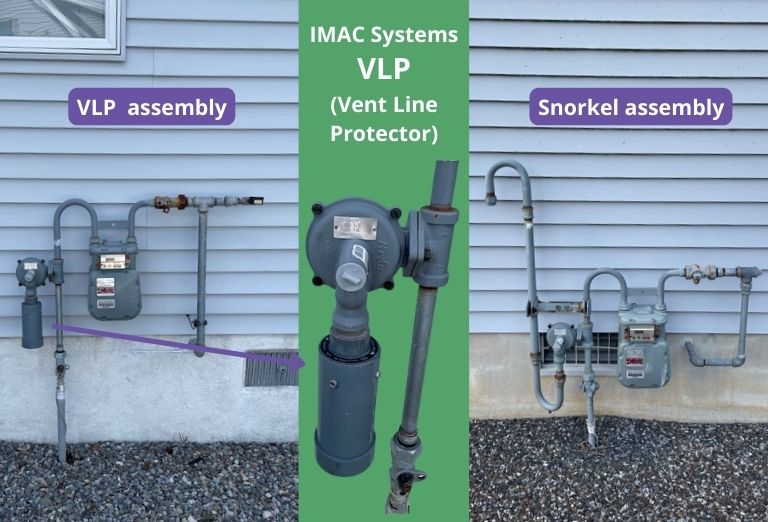

The IMAC VLP (vent line protector) has protected gas regulators in flooding events for nearly ten years. It is a mechanical device that seals off an open regulator vent when it becomes submerged in flooding water, keeping water and debris out of the regulator and preventing damage and corrosion.

The VLP is used on houses and businesses in areas prone to flooding, such as coastal areas, facilities near rivers, low-lying areas, or in pits or below-ground applications. The VLP protects gas regulator vent lines from encroaching water. It guards natural gas and LPG lines. The VLP is installed on the vent line and usually is “open.” However, if water enters the vent line via the VLP, a float will seal the vent line shut. Then, the float will drop when the water recedes, re-opening the vent to its normal position.

The Vent Line Protector addresses National Fuel Gas Code NFP 54 / ANSI Z223.1, which states,

Regulator vents shall be designed to prevent the entry of water, insects or other foreign materials that could cause a blockage. At locations where regulators might be submerged during flooding, a special anti-flood type breather vent fitting shall be installed….”

VLP Preferred Over Elevating the Regulator Vent (Snorkel Assembly)

Limited proactive measures exist to prevent water damage to regulators in low-lying flood areas. One alternative is a snorkel assembly that raises the vent but produces a more costly and less aesthetic solution to the easy-to-install and inexpensive VPL.

Another scenario where the VLP may assist is in high snowfall areas, where snow routinely blocks regulators’ vent openings. A VLP could provide extra protection from intruding moisture and save the regulator from damage and corrosion. If you have experience using the Vent Line Protector in a snow application, we’d love to hear your insights.

For more information on this gas metering accessory, call (303) 697-6701, message us, or visit our Sales Team page to connect with a salesperson.

Here is a video explaining venting guidelines to ensure your gas regulator works efficiently.

You reference not to install ” excessive fittings or long runs” on regulator vent piping, what length is considered to long? I have a project with 4 vented regulators and while the vent piping is attached the units starve for fuel, If we disconnect the vent piping they operate normally. Does a standard or chart exist that states that for every 10-15 ft to increase the vent pipe size until it is out of the building? I am assuming that the regulator orifice are sized correctly as the units would not operate properly with the vent disconnected. I was ask to try to resolve this issue as the installing contractor is no longer involved with the project.

I’ve also had some regulators with little to short runs for me inside homes and also outside that would make a vibration or harmonic sound with the vent line connected which was well under ten feet including the fittings some would sound like they were hunting on a single unit never could get an answer any thoughts?