4 Steps to Select the Correct Natural Gas Flow Meter

Accurate gas flow measurement begins when selecting the correct gas flow meter for an application. Here are four steps to help choose a natural gas flow meter, along with a flow meter comparison and a flowmeter selection guide.

Need help selecting a flow meter?

1. Understand the Application.

Before selecting your flowmeter technology, understand the application. In a recent post, we provided tips to consider when choosing a gas flow meter technology. To paraphrase, better understand the application by determining:

- What is the purpose? Why do you need the meter? Is it for custody transfer, submetering, monitoring, or industrial process gas? Do you need mass flow or volumetric flow? What is your budget?

- What is the gas type? Single gas or a mixture? What is the operating flow range, accuracy requirement, process temperature, and pressure? Is the gas dry and clean? Alternatively, wet, corrosive, or dirty?

- Where is the meter intended to be installed? What are the environmental conditions? Will there be extreme temperatures? Is there good straight run? Are there regulations to consider? Noise or vibration concerns?

- What do you need from the meter? Do you need a totalizer or a local display? What are your calibration expectations? Do you need to be able to upgrade the meter to advanced electronics? What are your maintenance requirements?

Gathering this information will help you make an intelligent selection to measure your natural gas.

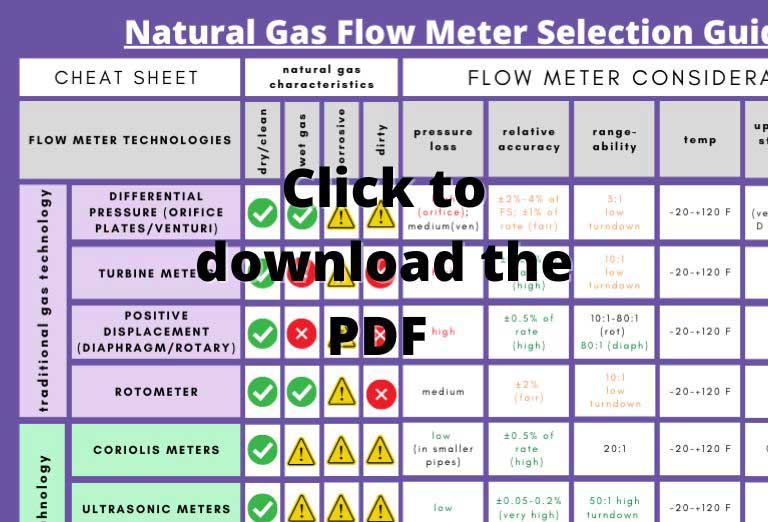

2. Review our Natural Gas Flow Meter Selection Guide.

After understanding the application, review our cheat sheet to help guide which technology to consider. Click on the image to view this guide. Additionally, keep in mind that there are four different natural gas flow meter types:

After understanding the application, review our cheat sheet to help guide which technology to consider. Click on the image to view this guide. Additionally, keep in mind that there are four different natural gas flow meter types:

- mass flow

- volumetric flow

- velocity meters

- inferential flowmeters

3. Flow Meter Comparison and Selecting the Correct Technology

After reviewing the selection guide, you likely have honed in on one or two meter types. Compare these technologies to understand each flowmeter type’s operation principle, advantages, and disadvantages. Here are convenient links to the different meter types to guide your review.

- Coriolis and thermal mass flow meters measure mass flow and are new gas technology. The Coriolis is used in the fiscal measurement of natural gas, while thermal mass flow meters measure industrial process gas flow.

- Rotary and diaphragm gas meters are positive displacement or PD meters and are a traditional gas technology used for utility billing applications or custody transfer of natural gas.

- Turbine meters are a conventional technology and velocity-type device that measures natural gas for custody transfer applications.

- Ultrasonic flowmeters are considered a new gas technology; they measure natural gas for custody transfer applications and are velocity-type meters.

- Vortex gas flow meters, another velocity-style meter, measure natural gas primarily in industrial applications as they are a late-comer to custody transfer approval.

- Differential pressure flow meters (or DP meters) are inferential meters and include the orifice plate, Pitot tube, Venturi meter, and V-Cone meters. They are traditional technology and are approved for custody transfer.

- The Rotameter is a conventional gas technology used as an industrial flow meter to measure the volumetric flow rate of fluids in a closed tube.

4. Still unclear? Have questions? Call 303 697-6701.

Our dedicated staff is happy to walk you through the selection process and may have recommendations on some natural gas meters for your application.

nice input

nice information

We are looking more insight for flow meter selection