What is the Thermal Mass Flow Meter Principle?

There are many different types of natural gas flowmeters that we can categorize by operating technologies, which are vortex shedding, Coriolis technology, differential pressure, positive displacement, turbine, ultrasonic and thermal. There are pros and cons of using each flow meter technology. Here we explain the thermal mass flow meter principle of operation.

Request Information on Sage Metering

What is a thermal mass flow meter?

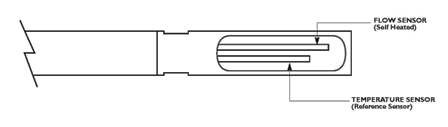

A thermal mass flow meter measures gas flow based upon the principle of heat transfer. Heat is introduced into the gas flow stream, and then the rate of how the heat dissipates is measured. For this to work, the meter needs a probe or “flow body” containing two sensors (resistance temperature detectors) to contact natural gas within the pipe.

Principle of Operation

One sensor is heated and serves as a self-heated flow sensor, while the other is a reference sensor and measures the gas temperature. As gas flows by the heated sensor (flow sensor), the flowing gas molecules carry heat away from the sensor, so the flow sensor cools, and energy is lost. The temperature difference between the flow sensor and the reference sensor has changed, and within a second, the circuit heats the flow sensor to replace the lost energy. The mass flow is calculated based upon the energy (electricity) required to restore and maintain a constant overheat temperature.

|

Diagram courtesy of Sage Metering – gas mass flow meters

Among the advantages of thermal mass flow meters is there are no moving parts or orifices, eliminating bearings and preventing undetected shifts in accuracy. They also don’t require temperature or pressure corrections and provide good overall accuracy and repeatability over a wide range of flow rates. This meter style calculates mass flow rather than volume and is one of the few categories of meters that can measure flow in large pipes.

The thermal mass flow meter is cost-effective and accurate, making it an excellent choice for most natural gas mass flow applications.

I would like to inquire for the thermal flow meter which will be best suited for our Lamson and Spencer multistage centrifugal air blower machines