7 Advantages of Steel Blue Prefabricated Meter Sets

In the dynamic landscape of natural gas distribution, efficiency, reliability, and safety are critical factors driving innovation. Prefabricated meter sets have emerged as a revolutionary solution, offering numerous benefits over traditional on-site assembly methods.

Steel Blue Fabrication Introduction

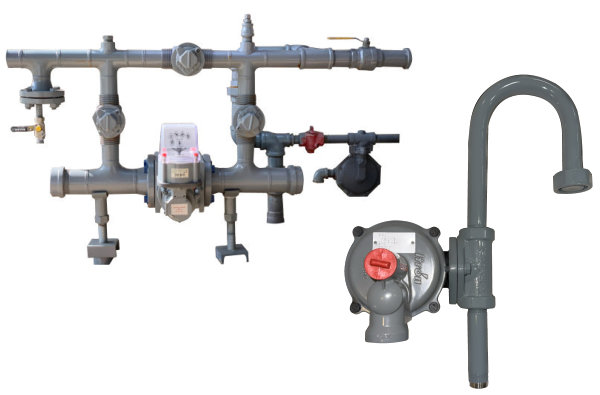

Steel Blue Fabrication manufactures prefabricated meter sets for diaphragm, rotary, and turbine gas meters in residential, commercial, and industrial settings. The company is based in Avon, Florida, and its welders are API 1104 certified.

Here are seven advantages of choosing prefabricated meter sets and how they have transformed the industry. They have significantly reduced on-site installation time, improved safety standards, and enhanced the overall quality of gas distribution systems.

#1: Time and Cost Efficiency

Prefab meter sets can reduce on-site installation time by as much as 50-70% compared to traditional methods. With most of the assembly done off-site, fewer person-hours are required on location, significantly reducing labor expenses.

They can also minimize project delays from weather-related interruptions since the fabrication occurs in controlled factory environments. In a nutshell, faster project completion means quicker service activation and revenue generation.

#2: Consistent Quality Control

Prefab meter sets are factory-controlled assemblies produced in climate-controlled environments with specialized equipment to ensure precise assembly. Each unit is subject to rigorous testing as it undergoes comprehensive pressure and functional tests before leaving the factory.

Field assembly errors can occur when using on-site technicians with varying skill levels and during challenging field conditions. This risk is reduced when using prefabricated meter sets. Standardizing the sets throughout the system ensures consistency across multiple installations, making future maintenance and upgrades more straightforward.

#3: Enhanced Safety

The sets are assembled in a controlled environment, which reduces risks associated with on-site welding, heavy lifting, and working at heights. Steel Blue has comprehensive safety checks to catch potential issues early, using multiple inspection points during fabrication.

The sets are assembled in a controlled environment, which reduces risks associated with on-site welding, heavy lifting, and working at heights. Steel Blue has comprehensive safety checks to catch potential issues early, using multiple inspection points during fabrication.

This process allows users to minimize job site dangers during installation, such as adverse weather, traffic, or other unexpected conditions. Additionally, it is easier for the user to comply with OSHA and other safety standards, as the sets are designed and assembled with these standards in mind, reducing the risk of non-compliance.

#4: Customization and Flexibility

Steel Blue creates custom fabrication, meaning the sets are designed to meet specific flow rates, pressure requirements, and space constraints. The sets are easily adaptable for residential and large industrial projects.

The prefab sets accommodate various environmental factors, local codes, and unique project needs. They also make integrating advanced technologies and preparing for potential system upgrades easier.

#5: Simplified Logistics

Using Steel Blue Prefab meter sets simplifies and streamlines delivery, saving transportation costs and streamlining scheduling for a single-unit delivery. This may even reduce the need for on-site storage of components, reducing the risk of theft or damage.

Inventory management is more straightforward when tracking complete units rather than multiple individual components. They also can help optimize project efficiency through just-in-time deliveries.

#6: Improved Regulatory Compliance

Prefab meter sets adhere to industry regulations and ensure uniform compliance. The fabricator maintains a detailed record of materials, assembly processes, and testing for traceability.

When using these products, the design’s preapproval expedites the on-site regulatory inspections. Established factory processes make meeting quality management standards easier.

#7: Long-term Reliability

The prefab assemblies are manufactured with high-quality materials in controlled conditions, which can lead to longer operational lifespans. Precision factory assembly often results in fewer issues and less frequent maintenance needs, ensuring that the systems remain reliable over the long term.

The optimized designs and factory testing contribute to more efficient and reliable operation. The standardized sets make diagnostics and repairs more straightforward for field technicians with easier troubleshooting.

Conclusion: Prefabricated meter sets a leap forward

Steel Blue prefabricated meter sets represent a significant leap forward for natural gas distributors. They provide:

- Time and cost savings

- Enhanced safety

- Superior quality control

- Improved long-term reliability

These units are becoming the preferred choice for gas utilities and contractors alike. As industry leaders like Steel Blue Fabrication continue to innovate and refine their prefabricated solutions, we expect to see even greater efficiency, safety, and performance advancements across the natural gas distribution sector.

Contact us now to discuss your current fabrication project with one of our trained specialists.