Thermoelectric Generators (TEGS) Application in Cathodic Protection

The Global Power Technologies thermoelectric generator for cathodic protection provides remote CP sites with cost-effective, reliable, and continuous electrical current.

CP to Control Corrosion

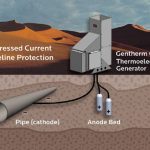

The natural gas industry uses cathodic protection to control corrosion of pipelines, wellhead casings and tanks, steel pier piles, and offshore oil platforms. Thermoelectric generators (TEGs) provide cost-effective, reliable, and continuous electrical current to difficult-to-reach CP sites.

A metal pipeline is usually anodic; supplying an electric current makes the pipe passive or cathodic. As long as the electrical flow arrives at the cathode (pipeline) faster than oxygen, corrosion is prevented or significantly slowed.

Thermoelectric Generator for Cathodic Protection (TEGS)

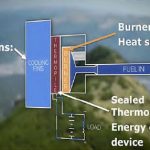

Thermoelectric generators produce electrical power by directly converting heat from fuel combustion into electricity, offering a dependable supply of continuous current. The generators are usually located near the ground bed and are fueled by gas from tanks, wellheads, or pipelines. The output current can be adjusted using an integral variable resistor, allowing it to match the ground bed resistance.

While a CP Interface design will vary depending on the TEG Model, the following are general offerings:

| Cathodic Protection Panel | Package Includes: | Options: |

|

|

|

Global Power Technologies offers several thermoelectric generator models for a CP application. Indeed, you may read more, download an application brief, or ask to speak with one of our sales representatives.